How To Install Metal Ridge Cap On Dormer

How to Install Metal Roofing

Learn how to become covering layers right with these metallic roofing tips.

![]() Fourth dimension

Fourth dimension

Multiple Days

![]() Complexity

Complexity

Avant-garde

![]() Toll

Toll

More than Than $5000

Introduction

Wi th its sleek, modern wait, metal panel roofing was our first pick for the Getaway. It has no visible seams and is maintenance free — even a calorie-free pelting will wash leaves and sticks off the roof. Fifty-fifty better, information technology won't grow moss and algae in the shade of the Wisconsin woods.

A metal roof volition reduce cooling costs by reflecting heat and concluding 50 to 70 years. Armed with a bones understanding of the beefcake of a metallic roof, along with a few tips, you can install one yourself in simply a few days.

Pro tip: Information technology's all about the layers. When information technology rains, a roof sheds water from one layer to the next until it runs off the roof. Build roof layers the correct manner and your home will stay dry inside for its entire life.

Tools Required

Materials Required

- Metal Roofing Panels

- Water ice and Water Shield

- Roofing Nails

- Eave Trim

- Gable Trim

- Ridge Cap

- Sidewall Flashing

- Self Tapping Roofing Screws

- Metal Roofing Sealant

- Inside Foam Closure Strips

- Outside Foam Closure Strips

- Butyl Tape

- Roofing Vent Boots

Project step-by-step (11)

Stride 1

Apply the underlayment

-

The first layer on tiptop of the plywood or OSB roof deck is underlayment. For this, nosotros chose a cocky-healing water ice-and-h2o membrane to protect the shallow-pitched roof deck.

-

The tricky part in laying the underlayment is keeping it flat and wrinkle-costless. Unroll the underlayment beyond the roof while removing the bottom half of the adhesive backing. Overlap the previous layer by 6 to eight inches. Once the underlayment is rolled out, cut it flush and pull the rest of the adhesive bankroll out from underneath.

Step 2

Lodge panels to fit

- If possible, avoid seams in your roof. They don't look great, and it could lead to water getting underneath the panels.

- I had our metal roofing panels cutting to fit the length of our roof. They were most 32 feet long and had to exist delivered on a flatbed trailer. Of course, you lot'll demand a big elevator to hoist the panels on top of the roof. If yous don't have 1, you'll accept to guild more than manageable lengths.

Footstep 3

Bend trim ends closed

- Earlier you install the trim, cut and bend the leading end to wrap information technology around the corner. Make a series of one-inch cuts with aviation snips at each curve to create tabs. Fold the tabs in with a hand seamer to meet a wall or a corner, or to close a gap created by the trim. Each trim is a different shape, requiring unique cuts and bends.

Pace 4

Fasten eave trim

- Install the eave trim tight to the fascia and fasten it to the roof deck over the underlayment with i-inch roofing nails. In warmer climates, the eave is attached before the underlayment. In northern Wisconsin, where ice dams are common, we install these atop the underlayment to protect the entire roof from dams.

Step 5

Splice and overlap trims

- Where two trim ends meet, you'll splice them together. First, cut the bottom hem of the underlapping trim at an angle. After installing the underlapping trim, utilize sealant on top. Pry open up the bottom hem of the overlapping trim and slide information technology over the angle-cutting hem of the underlapping trim.

Step 6

Snap a square reference line

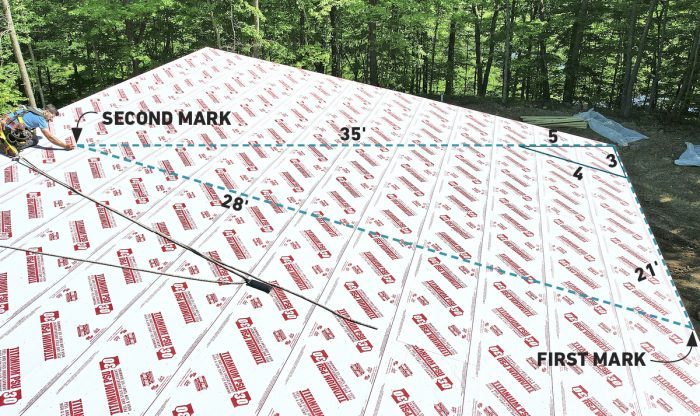

- A foursquare reference line is important for installing roofing panels evenly. Use the 3-4-5 method to establish a reference line xc degrees to the eave.

- Kickoff, make a mark along the eave three feet (or whatsoever multiple of three) from the corner. At that mark, measure four feet (or the same multiple of four) toward the ridge. Then, from the original corner, measure five feet (or the same multiple of v) and marking where it intersects the second mark.

- Snap a line from the get-go three-foot mark through the intersection of the second and third marks. Since the Getaway roof is larger, I measured to 21 feet, 28 anxiety and 35 feet (seven times three, iv and five) to make my square reference line.

Footstep 7

Fix the panels

- Place each metal console on an inside foam closure strip. These strips are shaped to fit the corrugated underside of the panel and keep bugs and water from getting underneath.

- Position the closure strips along the eave well-nigh i inch from the border and stick them to the panels with butyl tape. Run a bead of sealant on top of the closure strip, and then set your panel so it overhangs across the eave past one inch. Adjust the panel so any measurement from it to the reference line is the aforementioned at the top and bottom.

Pace eight

Bulldoze screws simply right

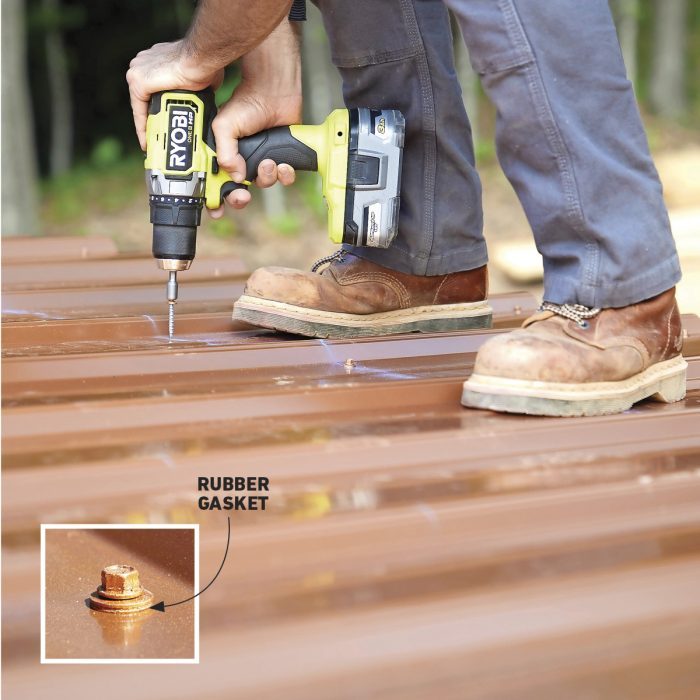

- Fastening the panels only correct is the key to a watertight roof. Here is what you should know:

- At the eave, place screws on both sides of every rib and lined upwards to go through the cream closure strip.

- Each row should be spaced no more 24 inches with one screw at each rib on the overlapping side.

- Starting time at the lesser, fastening beyond the panel in rows, working toward the ridge.

- Drive screws to seat flat on the roof; a crooked screw won't seal.

- Don't over-tighten or under-tighten. Tighten only enough to compress the rubber gasket to the edge of the screw head, not past it.

- Clean upwardly any metal shavings or burrs right abroad. They volition rust.

Footstep 9

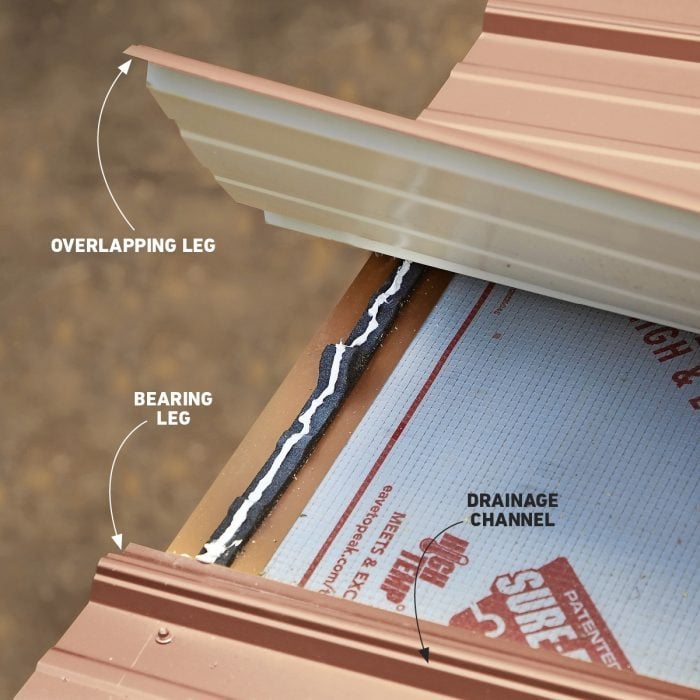

Overlap the panels

- The 2 edges of the metal panels are dissimilar. The border that overlaps has a shorter rib leg that doesn't contact the roof surface when laid flat. The rib on the underlapped side has a drainage or anti-siphon channel to keep water moving toward the eave. Overlap the last rib on each console; they should nest together perfectly.

Step 10

Encompass the rake edge

- After all the panels are fastened, it'south time to attach the gable trim. This cleans upwards the edge of the console and keeps pelting and snowfall from getting under the roof panels and siding.

- After you lot bend the end of the trim to meet the corner at the eave, apply butyl tape on the underside of the trim where it lands on the apartment function of the roof panels. Press it in place and drive screws every 12 inches right over the butyl tape.

Step 11

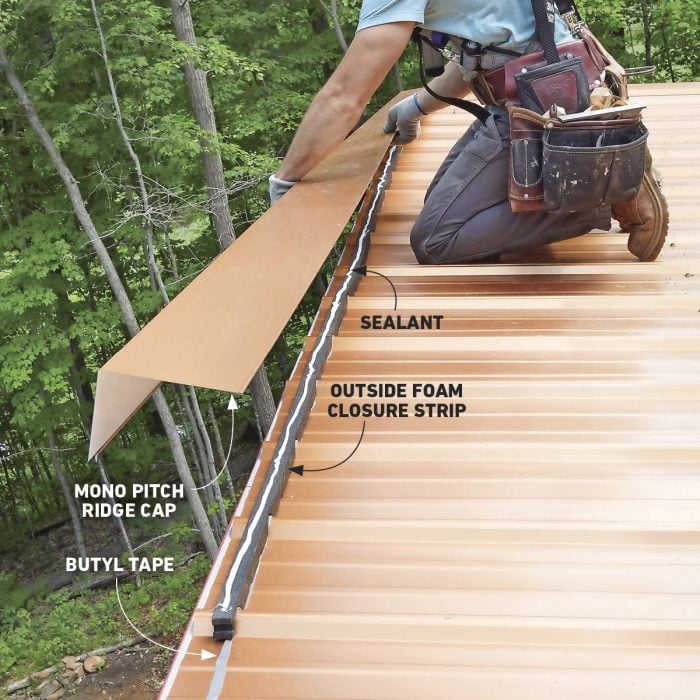

Secure the ridge cap

- To cap the roof, adhere a line of outside closure strips with butyl tape iv inches from the peak of the tiptop; this is where you'll fasten the ridge cap to the roof with screws. Apply a bead of sealant on the foam closure, and so fit the ridge cap on the peak and fasten with 2-inch screws to the roof deck through every rib.

- With the cap of the roof complete, all the water that lands on the roof volition exit the roof without e'er touching the underlayment.

Originally Published: August 23, 2022

Source: https://www.familyhandyman.com/project/how-to-install-metal-roofing/

Posted by: hoganyouttleste.blogspot.com

0 Response to "How To Install Metal Ridge Cap On Dormer"

Post a Comment