How To Install A Catalytic Combustor In A Wood Stove

Catalytic Combustor Wood Stoves

Catalytic Combustor Wood Stoves

Draft Aligning & Catalytic Wood Stove Puff-dorsum Repair

- Postal service a QUESTION or Comment almost installing, adjusting & troubleshooting catalytic combustor woodstoves

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

How to install, adjust & troubleshoot catalytic combustor woodstoves.

A wood-stove catalytic combustor improves the burning efficiency of a forest-burning stove to excerpt more heat from the firewood and at the aforementioned time to produce a significantly cleaner exhaust than that plant in the normal smoke produced past burning firewood.

This commodity series explains the methods of measurement and proper aligning settings for heating equipment.

Nosotros also provide an ARTICLE INDEX for this topic, or you can endeavour the page acme or lesser SEARCH BOX as a quick way to find information you need.

Wood Stove Catalytic Combustors

How does a Woodstove Catalytic Combustor Work?

The operating concept of a wood stove combustor is the same as that familiar to readers whose automobile uses a catalytic converter to make clean up their vehicle's exhaust. Catalysis is defined as the speeding-upwards of a chemical reaction by using a catalyst - an additive or agent whose presence speeds up a chemical reaction.

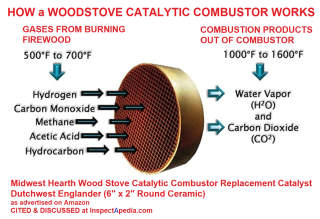

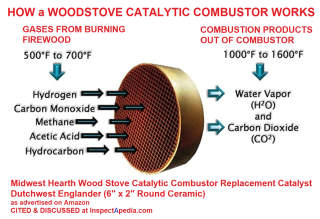

In a woodstove catalytic combustor, smoke and hot gases from burning firewood laissez passer through a honeycomb of material coated with platinum/palladium that, at sufficient temperature, pause down the components of the fume into less harmful end products, ideally, or in perfect operation, producing but carbon dioxide (COtwo) and water (HiiO).

[Click to enlarge any image]

The platinum or palladium (both may exist present) are the catalysts. The honeycomb pattern provides sufficient surface expanse to treat the book of exhaust passing through the combustor. High temperature is necessary for the catalytic process to occur.

The temperature rage at which a catalytic combustor in a woodstove tin can piece of work varies among specific catalytic combustor products and among forest stoves, but typically the device can operate as low as 250°F (121°C)in some designs, only more ofttimes at a higher temperature, betwixt 400°F (240°C) and 500°F (260°C).

To protect the combustor from damage or clogging with creosote and ash, the woodstove will include either a transmission or an automatic control to bypass the catalytic device when the stove is non at sufficient operating temperature.

Shown above, the Midwest Hearth wood stove catalytic combustor, as promoted on Amazon - retrieved 2022/12/09 original source: https://www.amazon.com/Midwest-Hearth-Catalytic-Combustor-Replacement [nosotros were not able to find an online installation manual for this woodstove catalytic combustor - only beneath nosotros provide contact information for the company - Ed.] This woodstove catalytic combustor replacement component sold for about $150. U.South. (Amazon Dec 2022). Midwest Hearth 3360 Quail Route NE Sauk Rapids, MN 56379 USA Web: https://midwesthearth.com/ Tel: 320-433-0008

Some forest stoves such as Vermont Castings' Intrepid 2, too include a permanently-mounted temperature probe that indicates the proper operating temperature range for the stove in guild that the catalytic combustor will work properly.

The catalytic combustor is typically located inside a special chamber in the wood burning stove where, protected from straight flame of the burning fire, the firewood'southward smoke and exhaust gases enter the bedchamber, mix with secondary air to complete combustion, and pass through the catalytic combustor where additional combustion occurs, finally entering the the stove's frazzle flue connector on the way to the building chimney.

Cost Benefits of Woodstove Catalytic Combustors

A truthful catalytic combustor used in some woodstoves reduces creosote build-up in chimneys, thereby reducing the risk of a creosote fire in the flue.

A woodstove catalytic combustor too will become more heat out of your firewood, reducing your firewood cost as well equally venting less forest-smoke contaminants to the surround around your building.

Manufacturers including Midwest Hearth shown here assert that using a catalytic combustor in a woods-stove will cut the stove'southward air pollution past 70%, reduce the adventure of a creosote chimney burn down by 75%, and reduce your firewood consumption by about xxx%. - cited beneath.

Sentinel out: exist certain to read the installation, use, and cleaning instructions for your woodstove and for its catalytic combustor. Some creosote removing products will damage the catalytic combustor unless the stove is run in bypass mode, while others are safe to use.

Most sources give about a x-twelvemonth life for a catalytic combustor element used in woodstoves. Because that the device costs less than $200. you should earn dorsum much more than than that in the cost of firewood burned, boosted rut obtained, and probably in reduced chimney cleaning cost besides.

Is it a Wood Stove Catalytic Combustor or a Wood Stove Heat Extractor?

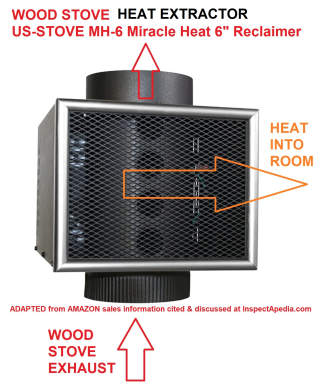

Below, a different device, a wood-stove oestrus extractor also sends more rut from a wood burning stove into the occupied space effectually the stove, but this is not a catalytic combustor, even though a spider web search for "woodstove catalytic combustor" will include this in the search render.

This is a heat extractor that is placed in line in the wood-stove'south frazzle flue vent connector between the stove and the chimney. Air passing through this heat exchanging device cools the woodstove frazzle and vents that reclaimed heat into the room

Watch out: both of these devices require careful following of the specific manufacturer's instructions for both successful role and for woods stove safety.

See this

- MIRACLE Oestrus Deluxe INSTALLATION INSTRUCTIONS [PDF] Models MHD-vi & MHD-8, United States Stove Visitor 227 Industrial Park Rd. Due south Pittsburgh, TN 37380, USA Phone: (800)750-2723 www.usstove.com , retrieved 2022/12/09 original source: https://world wide web.usstove.com/wp-content/uploads/sites/2/2020/08/MH6-MH8-Owners-Manual.pdf

Draft Management to Avoid Overheating & Puffing & Woodstove Puff-Backs at Catalytic Wood-Stoves

(2021-12-06) JR said:

During a "Back Puffing" event what would the draft measurement exist above the flue collar?

And let me also ask, is it unreasonable to await a catalytic wood stove to work properly with a draft at the collar between .04 and .08 inches of HtwoO ?

Properly pregnant no fumes being pushed out during performance.

Illustration, one of three models of the Blaze-King KE40 catalytic combustor woodstove cited in more detail below.

[Click to enlarge any image]

@JR,

Brusk answer: check with what your manufacturer says, or start wit 0.05" of water column. You also desire to check the operating temperature of your stove and you want to clinch that the catalytic combustor remains bypassed until the stove is at proper operating temperature.

In your initial question you asked about draft associated with a "puffback" and we thought y'all were referring to the explosive force that we depict below, associated with a malfunctioning oil burner.

But from the ensuing discussion it looks every bit if we're actually discussing a type of "puffing" or "puff-back" that occurs specifically in catalytic-type forest stoves - wood burning stoves that use a catalytic combustor to extract more heat out of the burned-wood than a conventional wood stove.

So we've organized our give-and-take and advice under this topic:

Catalytic Wood Stove Puffbacks: Draft Control to Avoid Overheating & Puffing or Puff-Backs

What'south the difference between a smoke-puffing woodstove and an oil-burner puffback?

Definition of an Oil Burner Puffback

An oil burner puffback explosion is a sudden, brief explosion: the ignition of collected united nations-burned fuel in an oil burner heated device like a h2o heater, furnace, or boiler.

During that brief interval (seconds) there will exist extreme back pressure in the combustion chamber. It seems certain that at that moment there volition exist no negative typhoon in the chimney merely rather an extremely positive one in the chimney - as the forces of the puffback explosion not only blow soot out all over the building (typically a lot of soot exits at the barometric damper and more at other boiler or furnace openings such as combustion air inlets).

That oil burner event is unlike than "puffing" or "puff-back" for catalytic woodstoves, although it is clearly an easily confused distinction.

For readers concerned with oil burner puffbacks, please come across this divide commodity:

OIL BURNER SOOT & PUFFBACKS

Back-puffing or puffs of smoke exiting a woodstove using a catalytic combustor is different from an oil burner puffback.

Definition of Woods-Stove Dorsum-Puffing

Dorsum-puffing at a woodstove occurs when the wood stove typhoon is inadequate: the draft is insufficient to remove volatile or flammable gases from the wood stove fire-box fast enough.

The upshot is that highly-volatile gases accumulate inside the wood-stove's fire bedchamber where they accumulate in quantity and increase in temperature until the gases ignite, causing a flare-up of pressure or "puff" of burned gases inside the stove.

The result of that sudden extra pressure tin exist an aural "puff" sound followed past a burst or leak of smoke into the room through small openings in the forest stove, including from its combustion air intake openings.

What to exercise immediately if your woodstove is back-puffing

- Open the woodstove flue damper to increment the typhoon to let the woodstove'due south exhaust or smoke vent upwards the chimney more quickly

- Open the woodstove'south combustion air to allow increased combustion air into the fire chamber then that un-burned gases don't accumulate.

- Check the status of your firewood. Very-dry firewood may be burning hotter and faster than you lot anticipated, producing gases faster than the woodstove can burn down-them.

If your firewood is quite dry and burns quickly and hot, take care not to over-load the firebox with too much wood: build smaller fires.

- Test your woodstove typhoon for adequacy. We draw this procedure

at WOOD STOVE DRAFT Exam

and just below nosotros draw in more than-detail the diagnosis and cure of catalytic woodstove back-puffing.

Set Catalytic Woods Stove Draft Level to Avert Puffing

Illustration: adapted from Midwest Hearth Forest Stove Catalytic Combustor Replacement Catalyst: Dutchwsest Englander, advertisement and product clarification provided at Amazon.com 2022/12/09. This is a six" diameter x ii" thick catalytic combustor.

Illustration: adapted from Midwest Hearth Forest Stove Catalytic Combustor Replacement Catalyst: Dutchwsest Englander, advertisement and product clarification provided at Amazon.com 2022/12/09. This is a six" diameter x ii" thick catalytic combustor.

Information technology's significant that the "experts" over at the US EPA, writing on the disquisitional safe of proper draft at a wood stove, catalytic blazon, mention "typhoon" x times in their write upwardly without ever giving a wood stove draft number.

Why?

I suspect that they, like I exercise, think the proper typhoon for safe performance of a catalytic woodstove is probable to depend on both the specific wood stove make and model simply also on the site and venting arrangement or chimney type, height, etc.

See

- CATALYTIC WOODSTOVE INSTALLATION - [PDF] U.S. EPA, Ecology Protection Agency - retrieved 2022/12/05 original source: https://world wide web.epa.gov/sites/default/files/2013-09/documents/catalytic.pdf

Besides much draft in a catalytic combustor forest stove causes overheating and damage and is unsafe.

Too little draft in a catalytic combustor woods stove causes smoke backup and possibly wood stove "puffing" and bottleneck soot formation.

Sentinel out: some catalytic combustor woodstove companies and discussions warn that improper draft in those heaters can damage the equipment or exist unsafe. For example, likewise much draft can draw flames into the interior of the catalytic combustor, damaging it.

Proper draft is achieved by a combination of features including flue size, shape, routing, height, chimney cap, terrain features nearby, wind directions, and more than.

Draft vs. Temperature: So what's the correct draft by measurement?

In our research so far, the manufacturer doesn't await you to measure out catalytic wood stove draft; rather they think you'll monitor its temperature.

Platonic temperature appears to exist no college than g°F and no less than 250°F and for some models the minimum temperature may need to be 400°F or 500°F.

Watch out: 1800°F is dangerous enough that the stove should close down. (Measured at the catalytic combustor?)

But if you are measuring catalytic wood stove draft:

Don't allow the draft to exceed .06" of water draft (or a unlike number like 0.05" water cavalcade typhoon if specified by the maker of your specific stove).

Check the installation and operating instructions for your specific catalytic wood stove manufacturer and make.

As well see

- PRINCESS CATALYTIC Forest STOVE INSTRUCTIONS [PDF] BlazeKing, Valley Condolement Systems Inc., 1290 Commercial Way, Penticton, BC, V2A 3H5, Canada Tel: 250-493-7444 Web: world wide web.blazeking.com E-mail: info@blazeking.com

Note: this document discusses draft adjustment for woodstoves using a catalytic combustor, but gives NO draft measurement numbers. - retrieved 2022/12/05

- CATALYTIC WOOD STOVE Operation [PDF] (2014) prepared for Urban Hearth, 6154 Highway 43 Perth, Ontario K7H 3C7 Canada, Tel: ane-866-377-1796, a distributor of Jotul, BlazeKing, STUV, KozyHeat and other heating and BBQ appliances, website: https://urbanhearth.ca/ by Gulland Associates, - retrieved 2022/12/05 original source: https://urbanhearth.ca/handouts-new/45-how-to-operate-your-catalytic-stove/file

As an example of empirical observations that accost proper catalytic woodstove draft, we have:

How exercise you know if your draft is excessively high or depression?

Symptoms of too much typhoon include an uncontrollable burn or a glowing-red stove part.

A sign of inadequate typhoon is fume leaking into the room through the stove or chimney connector joints, low rut, and dirty glass.

Draft Testing:

An easy mode to exam your chimney draft is to shut the stove's damper, wait a few minutes to permit the airflow stabilize, and then see whether you tin vary the force of the fire past swinging the air control open and closed.

Results are not always instant; you may need to wait a few minutes for a change in the air command setting to accept an effect on the burn.

If there'due south no change, then the draft isn't strong enough yet to let you shut the damper, and you'll need to open it for a while longer and manage the burn with the air inlet until the draft strengthens.

If you lot go along rail of your burning habits and relate them to their effects on the stove'due south operation, yous'll be rewarded with good functioning and a condom system. - source: Vermont Castings cited just below.

- INTREPID WOOD STOVE CATALYTIC COMBUSTER INSTRUCTIONS [PDF] (2019) Vermont Castings Stove Co., 352 Mountain House Route , Halifax, PA 17032 U.s.a., Website: world wide web.vermontcastings.com - retrieved 2022/12/05

Excerpt:

Temperature Probe:

Your stove is equipped with a temperature probe which shows the operating range of the catalytic combustor. This is located on the back of the stove and is viewed from the top. If the probe indicator is beneath the operate goad range, add fuel or open the featherbed damper likewise let the fire to build.

Closing the bypass damper should and so result in an increase in goad temperature to within the operate catalyst range. If the probe indicator is above the operate catalyst range, the catalytic combustor is running to hot and may be damaged. In many cases, increasing the primary air can reduce the catalyst temperature and adding less forest with each loading can as well assistance if overheating is persistent.

Overly dry wood can too crusade overheating of the catalyst element. Do not add forest to the stove if the probe reads above the operate catalyst range.

This article has extensive and detailed (but not quantitative) advice on typhoon direction for catalytic type wood stoves.

1 more than reference,

- IDEAL STEEL HYBRID WOODSTOVE MANUAL [PDF] (2020) Gear Head Stoves, Woodstock Soapstone Company, Inc. 66 Airpark Route, West Lebanon, NH 03784 USA Tel: ane-800-866-4344 Website: world wide web.woodstove.com

provides more examples of catalytic blazon wood stove operating typhoon settings without using any quantitative data.

Lesser line on Catalytic Woods Stove Draft Level Numbers

Image higher up shows a draft gauge indicating -0.06" W.C. (h2o column). The few citations we found gave a measured draft for a catalytic blazon woodstove as operating at -0.05" of water column negative typhoon measured in the chimney above the stove.

All of the sources list other means to know if draft is also weak or too stiff.

To work effectively, the chimney that serves your wood stove, catalytic type, should have a draft capacity of no less than -0.05" H2o Column and should be able to produce drafts up to -0.08" WC but as our reader, JR, suggested, because site conditions, weather weather and other variables will at times require yous to call on the chimney for more draft simply to achieve the target 0.05" measured over the stove itself.

That is to say, you may want to set the draft at -0.05" simply to be reliable the chimney needs to exist capable of more draft, upward to around -0.08" -

read more about that need

at CHIMNEY RESERVE DRAFT MEASUREMENT

Lookout out: if you are really measuring draft on your catalytic wood stove and it is showing a very weak draft of -0.02", your draft is probably inadequate and won't draft properly, as shown in our photo below.

Thanks for the reference materials, and as you mentioned the stove manufacturers do not commit to actual numbers for draft requirements, for some reason I expect .

Thanks for the reference materials, and as you mentioned the stove manufacturers do not commit to actual numbers for draft requirements, for some reason I expect .

I am struggling with fumes exiting my new Blaze Rex KE40 catalytic forest stove, not smoke just off gas, from the smoldering process (gasification), beingness forced out through the door gasket.

I honestly believe these new Cat stoves are of bad blueprint and can allow toxic gases to leave into the home environment without notice, a serious danger to the wellness of users in my opinion and should exist investigated by the appropriate agencies.

Cheers for the added comment, information technology will be important for other readers who use catalytic woodstoves.

Nosotros're not experts on that specific woodstove feature but in reading through a number of catalytic forest stove installation manuals nosotros constitute it apparent that a lot of ink is given to proper draft management, and it'southward a mutual warning that inadequate typhoon is likely to produce puffing or back-puffing huffing from a catalytic wood stove.

I think the manufacturers will argue that if we follow their instructions the stove will work well. I've seen comments from people who were happy with their catalytic woodstove and others discussing damaged catalytic heat extractors - again blamed on failure to follow all of the manufacturer'southward instructions.

We'll continue to research this question.

My Opinion to engagement is that good pattern of whatsoever building system or feature should design for what people are likely to do, non what you want them to do.

For readers who demand a copy, here is the

- BLAZE-KING KE40 CATALYTIC WOOD STOVE Manual [PDF] (2021) - Blaze King, Valley Comfort Systems Inc., cited above, op. cit.., - retrieved 2022/12/05, original source: https://www.blazeking.com/wp-content/uploads/2021/07/180-KE40-july2021.pdf

Here are two excerpts from your stove transmission: Draft is the force which moves air into the appliance upwards through the chimney. The amount of draft created by your chimney depends upon length, offsets, insulating properties, obstructions (such every bit architectural design, trees), local geography and other factors. External forces, such equally outdoor temperature, wind, barometric pressure, topography, or factors inside the home (negative pressure level from exhaust fans, chimneys, air infiltration, etc) may adversely affect typhoon. Too much draft may cause excessive temperatures in the appliance and may damage the heater. An uncontrollable burn or excessive temperature indicates excessive draft. Inadequate typhoon may cause back puffing (spillage) into the room and plugging of the chimney, chimney cap or spark arrestor screen. Inadequate draft may cause fume to leak into the room through appliance or chimney connector joints. Poor draft can also lead to poor heat production and the inability for the combustor to remain agile in lower burn charge per unit settings. Loftier efficiency appliances, such as your Blaze King stove, may require some fine tuning of your chimney organization in gild to maximize functioning. Bonfire King cannot be responsible for external forces leading to less than optimal performance. and ROLE OF THE CHIMNEY Without a proper installed chimney, this appliance will not burn correctly. The role of the chimney is to pull the proper amount of air into the firebox for the purpose of complete combustion. Incomplete combustion will lead to more smoke and pollution of the outside air. A proper operating chimney will let the user to bask peak operation at all burn operating levels from low to high

DRAFTING PERFORMANCE

Lookout out: considering life-safety concerns use when measuring or adjusting the draft on fossil-fuel appliances and because different fuels and heater types use different settings and even measurement procedures, be sure to run across the specific typhoon measurement articles cited in the sections of the article above

...

Continue reading at CHIMNEY RESERVE Draft MEASUREMENT or select a topic from the closely-related articles below, or see the complete ARTICLE Index.

Or meet these

Recommended Articles

- CHIMNEY Typhoon & Operation

- CHIMNEY Superlative & CLEARANCE Lawmaking required acme of a chimney above the building roof.

- CHIMNEY INSPECTION DIAGNOSIS REPAIR - home

- CHIMNEY RESERVE Typhoon MEASUREMENT

- CREOSOTE Burn HAZARDS

- DAMPERS & DRAFT REGULATOR TYPES

- DRAFT MEASUREMENT, CHIMNEYS & FLUES

- FIREPLACE & WOODSTOVE CONTAMINANTS

- Wood STOVE OPERATION & SAFETY - dwelling house

- COMBUSTION AIR for WOODSTOVES

- DEFECTS List - HEAT, Woods Appliance

- FIRE CLEARANCES, WOOD COAL & PELLET STOVES

- FIREPLACE INSERTS

- Oestrus SHIELD SPECIFICATIONS for WOOD STOVES & PELLET STOVES

- PELLET STOVE CLEARANCE DISTANCES

- PELLET STOVE DRAFT Control

- PELLET STOVE MANUALS

- Woods FURNACE FAN LIMIT CONTROL

- WOODSTOVE DRAFT Control

- WOOD STOVE DRAFT TEST

- Woods STOVE, CATALYTIC PUFF-BACKS

- Forest STOVE INSTALL Catechumen

- Forest STOVE INSPECTION CHECKLIST [Certificate Image]

- Wood STOVE MANUALS

- WATER Force per unit area per Pes of HEIGHT

Suggested citation for this web folio

Wood STOVE, CATALYTIC PUFF-BACKS at InspectApedia.com - online encyclopedia of edifice & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or run into

INDEX to RELATED Manufactures: ARTICLE INDEX to CHIMNEYS & FLUES

Or use the SEARCH BOX plant below to Inquire a Question or Search InspectApedia

...

Ask a Question or Search InspectApedia

Try the search box only below, or if you adopt, post a question or comment in the Comments box beneath and nosotros will respond promptly.

Search the InspectApedia website

Note: appearance of your Annotate beneath may be delayed: if your annotate contains an prototype, spider web link, or text that looks to the software every bit if it might be a web link, your posting will appear afterwards it has been approved by a moderator. Apologies for the delay.

Technical Reviewers & References

Click to Show or Hide Citations & References

Publisher InspectApedia.com - Daniel Friedman

Source: https://inspectapedia.com/heat/Catalytic-Wood-Stoves.php

Posted by: hoganyouttleste.blogspot.com

0 Response to "How To Install A Catalytic Combustor In A Wood Stove"

Post a Comment